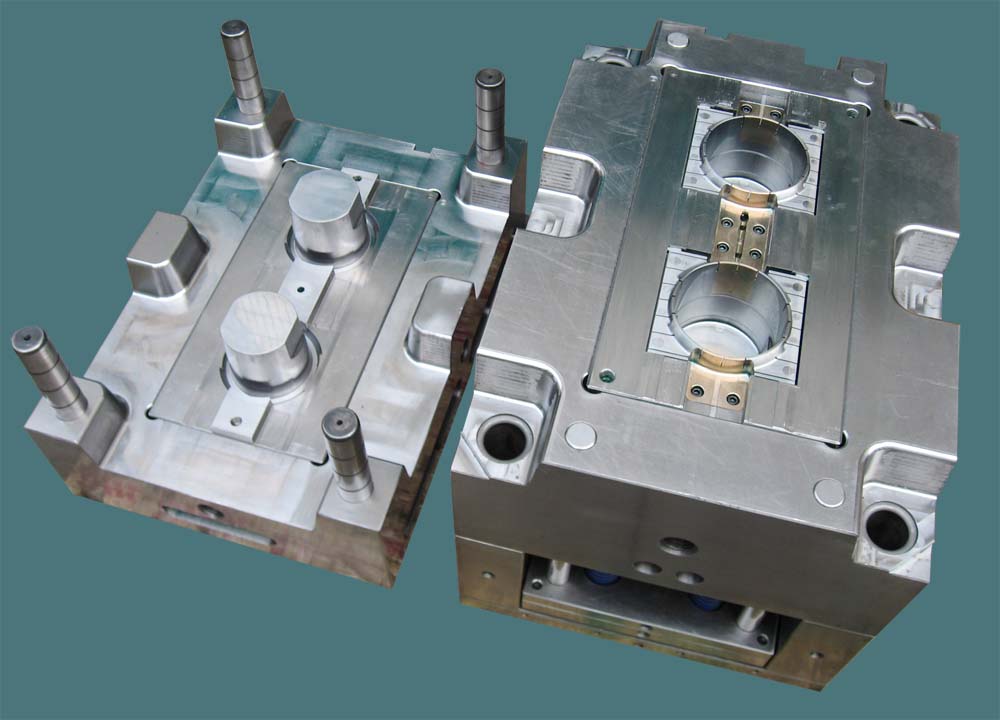

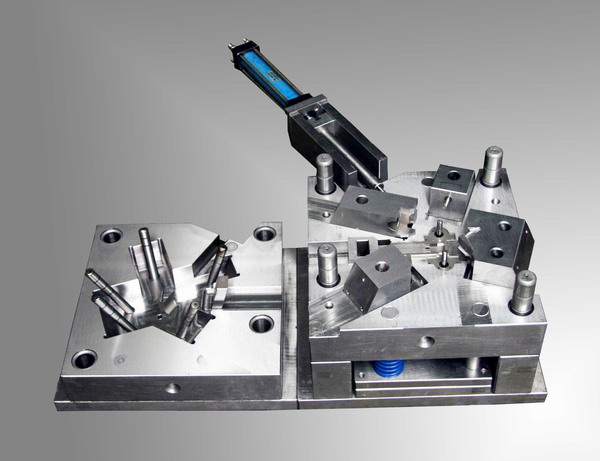

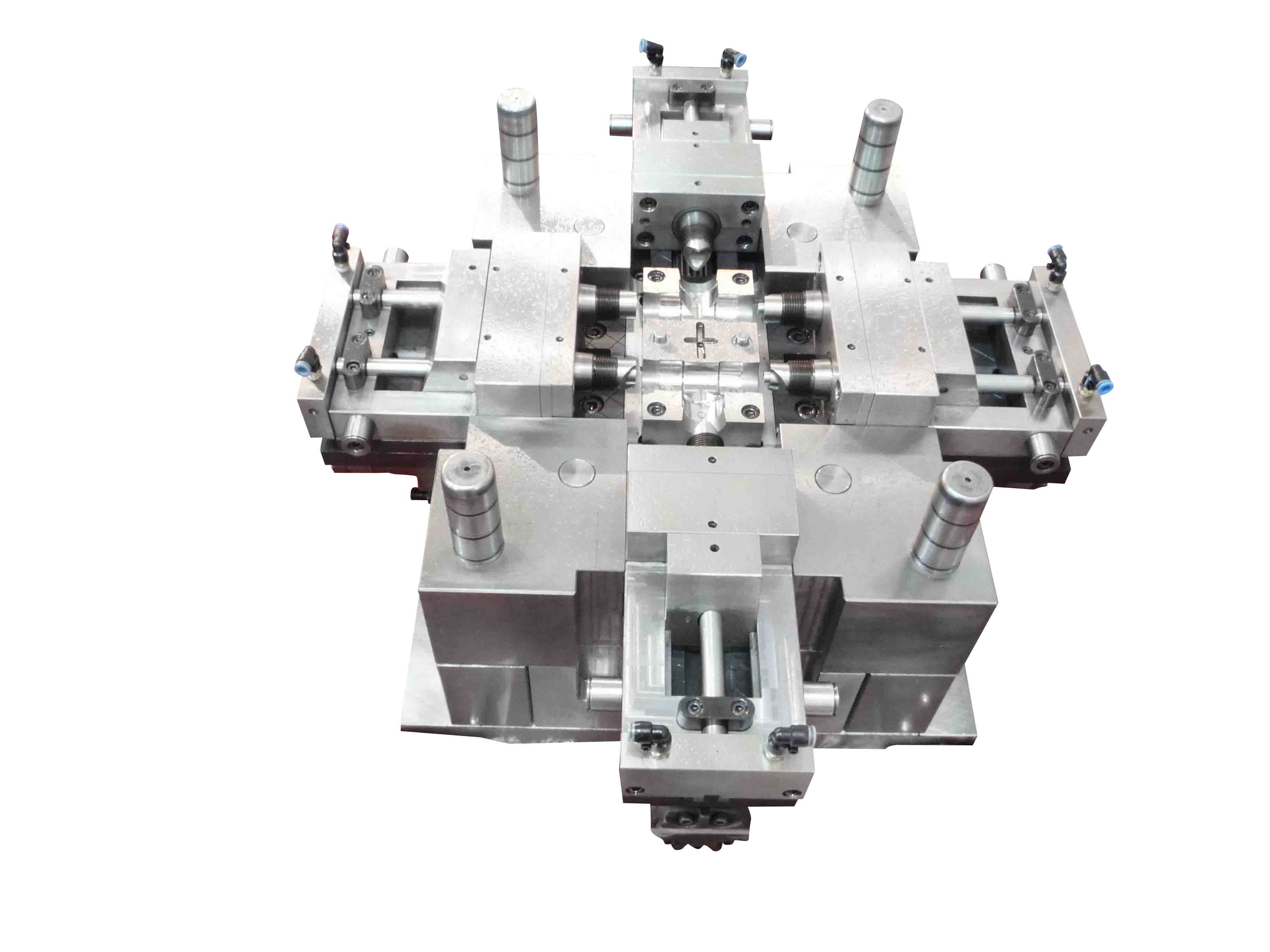

Generally the hard

chromium plating process is applied to machines, which are usually used under

high temperature, such as moulds, etc. However, what factors will affect the hardness

of chromium layer during the chromium plating process? We would like to share

some information with you as follows:

1. The relationship between the concentration of chromium

trioxide and hardness

When other process conditions remain unchanged, the hardness

will be high if the concentration of chromium trioxide is low. But if the

concentration is low, the plating solution will change fast and be unstable.

2.The relationship

between sulfuric acid content and hardness

According to normal

standard of chromium plating process, the ratio of chromium trioxide and

sulfuric acid should be kept at 100:1. When other concentration remain

unchanged, increase the sulfuric acid content and the hardness of chromium

layer will be higher correspondingly. However, when the ratio is 100:1.4, the

hardness of chromium layer will decrease if keep increasing the sulfuric acid

content.

3.The relationship between current density and hardness

At normal temperature, the hardness of chromium layer

will increase as the increasing current density. When the current density

reaches a limit, the hardness will tend to be stable.

4.The relationship

between stability of chromium-plating solution and hardness

At higher temperature

(about 65~75℃), the chromium layer plated by dilute solution is 15~20%

harder than those plated by concentrated solution; at lower temperature (about 35~45℃), the hardness of the chromium layer plated by dilute

solution is not much different from those plated by concentrated solution.

5.The relationship

between thickness and hardness of chromium layer

Generally, the hardness

of the chromium layer will get harder as the thickness increases, the hardness

will be the highest when the thickness reaches about0.2mm. After that, the hardness won’t improve any

longer even the thickness keep on increasing.

6.As the temperature getting higher, the hardness of the

chromium layer deceases observably

In order to improve the

current efficiency, hardness, gloss, covering power and throwing power, our

company has researched and developed additives which are specially designed for

hard chromium plating: HN-25 hard chromium plating process and HN-25R hard

chromium plating process.

They have common characters: the formula won’t contain

fluoride and won’t corrode the LCD area of workpiece; won’t corrode tin-lead

alloy anode and don’t need to use special

anode material; the cathode current efficiency is high

and can reach 22-26%; the thickness is

even and the deposit is bright; the layer has high microhardness and good anti-corrosion.

In addition, to

eliminate environmental pollution of chromium fog and save maintenance cost of

exhaust equipment, our company also has developed a chromium fog inhibitor,

HN-701 Chromium fog inhibitor. It not only can save the use of chromic acid,

but also improve the microcrack degree of chromium layer, enhance hardness of

layer and increase adhesion.