Analysis on Failure of Electroless Nickel Plating Solution Decomposition

As electroless nickel decomposing is a common problem, this time we will learn about the causes and notes about it.

When the

electroless nickel decomposes, the reaction does not only happen on plating

articles, but also in the plating solution and the gas evolution would be more than

usual. If put a little plating solution in a measuring cylinder, suspended

solid grains will appear. At this time, the plating process must be stopped immediately,

take out the articles and put them into cold water. And then pump the plating solution

through filter into the spare tank, adjust the component and the pH value of

the plating solution, and clean the plating tank with 30%~50% of nitric acid. After

removing the nickel layer which is inside the tank, the nitric acid solution

used to dissolve the nickel layer should be moved to another tank and wait to

be used the next time. Then, wash the plating tank with running water and pure

water. In the end, pump the plating solution with filter into the plating tank

again and have plating when the temperature rise to85℃.

If the plating solution still has decomposition, it is necessary to add stabilizer

appropriately and lower the pH value.

If pH value of plating

liquid were not adjusted appropriately, the decomposition of liquid would be disastrous.

That is because when putting alkaline pH regulators too fast into the solution,

it will cause partial over-high pH value, and the flocculent Ni(OH) would appear,

providing a large amount of solid surface with catalysis. Under the effect of

high temperature and high pH value, plenty of black Ni-P particles which the diameter

is only 1μm~3μwould be generated in the solution within just a few minutes. The area-mass

ratio of these particles reach 0.028㎡/g~0.76㎡/g. The composition contains are 85%~90% of nickel, 10%~15% of phosphorus and 1%~2% of impurity. Such a wide superficial

area will further accelerate the decomposition of solution, which leads to

solution invalid. Therefore, don’t adjust the pH value when plating.

When the bath

solution is decomposing, emergency measures must be taken. Firstly, add glacial

acetic acid into the solution, lower pH value to 3.5 or lower. And then pump

the solution with filter into the spare tank (or filter directly in the plating

tank) to have an adjustment, then it would resume. Adding dilute sulphuric acid

can restrain plating solution

from decomposition, while the concentration of sodium sulphate will be increased.

The sodium acetate produced when adding glacial acetic acid, which is a kind of

good buffer agent as well has wider allowance range.

According to the market demand, we

have researched and developed different kinds of electroless nickel products. Form low-phosphorous, middle-phosphorous to high-phosphorous,

we have full series eco-friendly electroless nickel plating products, pre-treatment

and traditional electroless nickel products, satisfying you with different

kinds and levels application requirements.

1. HN-1200 Alkaline Plastic Electroless Nickel

Plating Process

It is

suitable for the general plastic pretreatment process. For its low operating

temperature, stable bath solution and easy operating control, it shows

superiority on complex workpieces treatment process.

2. HN-1100 Bright Electroless Nickel

Plating Process

The bath solution

has extremely high resistance against metal impurity. The layer is full bright,

with good ductility and weldability.

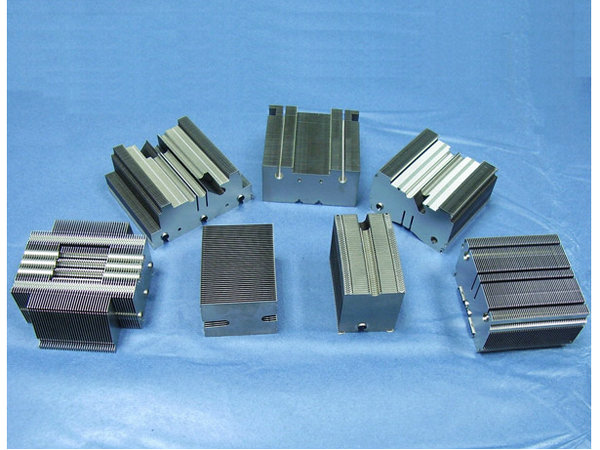

3. HG-GP (01) Eco-friendly High-phosphorous Electroless Nickel Plating Process

The layer phosphorus

content is high, with good corrosion resistance and ductility, can pass the nitric

acid etching test. The bath solution is stable and easy to control; has unique

additive system and extremely high resistance against metal impurity, can extent

the bath solution life. It is suitable for large molds and processes with high

wear resistance.

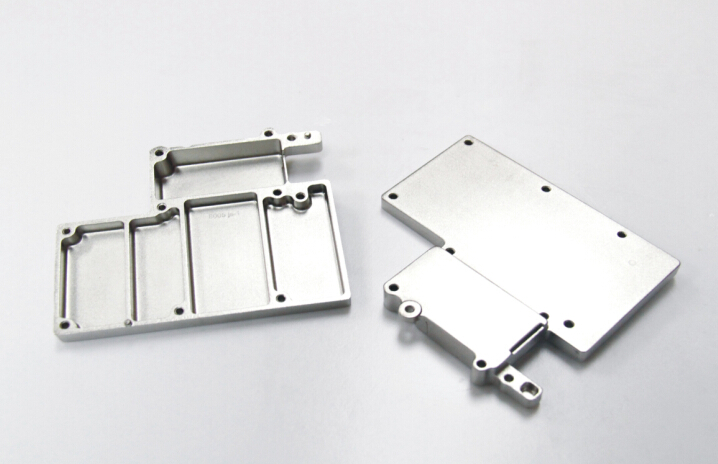

4. HN-2700 Aluminum Alloy

Electroless Nickel Plating Process

High malleability

of layer, good adhesion for different articles. Stable plating liquid, easy operating

control, unique additive system, high tolerance against metal impurities, can

extend the working time of liquid.

It has high

ductility and good adhesion for different matrixes. The bath solution is stable

and easy to control, has unique additive system and high resistance against

metal impurity, can extent the bath solution life.

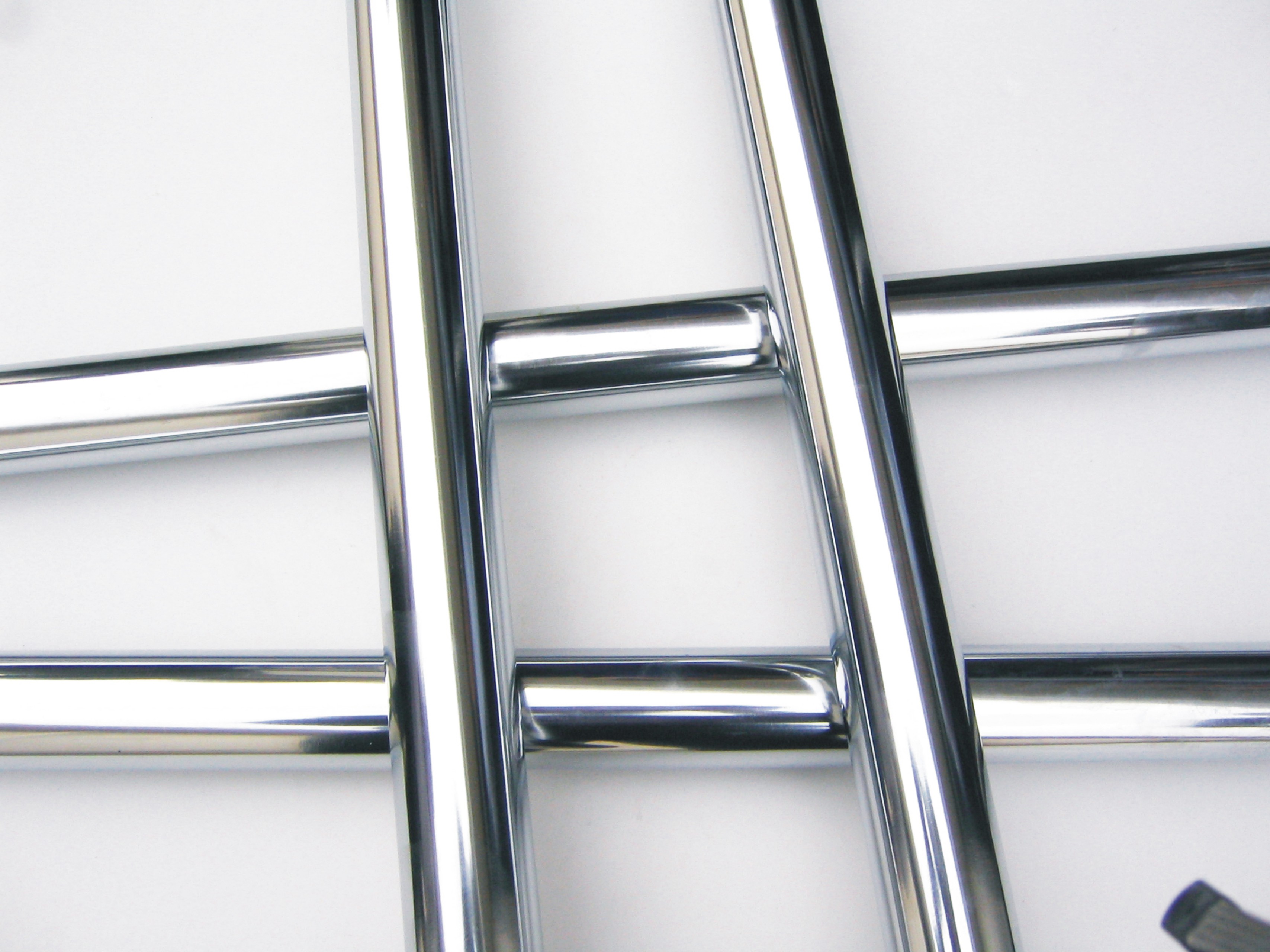

5. HN-2800 Full-bright

Electroless Nickel Plating Process

The layer is full

bright with good ductility and has good adhesion for different

matrixes. The bath solution is stable and easy to control, has unique additive

system and high resistance against metal impurity, can extent the bath solution

life.

6. HN-LP Eco-friendly Low-phosphorous Electroless Nickel Plating Process

It has good layer

ductility and good weldability. The bath solution is stable and easy to control,

has unique additive system and high resistance against metal impurity, can

extent the bath solution life; does not contain Pb, Cd or Hg, meeting the

environmentally friendly requirements.

7. HN-ENW Electroless Nickel Plating Stabilizing Agent

for Plastic Plating

It has good stability of bath solution and won’t affect

its activity; fine grained deposit and is not easy to have skipping plating, especially

suitable for plastic alkaline electroless nickel plating process. It is

environmentally friendly and does not contain heavy metals, like Pb, can meet

the export standard of some developed countries like EU, America, Japan, etc.