As the latest achievement in the development of rare earth permanent magnet, NdFeB magnetic material is called the king of magnet because of its excellent magnetism. NdFeB magnet is artificial and an umbrella name for powerful magnets and its chemical formula is Nd2Fe14B. So far, it is the most powerful permanent magnet. The main raw materials of it are neodymium, praseodymium, pure iron, aluminum, ferroboron and other rare-earth material. Because of its high-performance, NdFeB magnet is widely used in energy, transportation, machine, medicine, IT, household appliances, etc. With the development of knowledge economy, more new applications will be exploited and it will bring a wider market prospect for NdFeB industry.

NdFeB material contains a lot of neodymium and iron and it is easy to rust. Therefore, NdFeB magnet must have surface treatments, the normal layers are nickel, zinc and copper, etc.

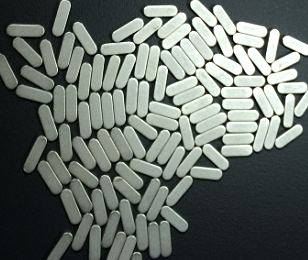

NdFeB material is not easy to be plated for having negative potential, high brittleness, porous structure and its flake parts are easy to stick together. For example, for nickel-plated NdFeB parts, nickel layer has magnetism, it would generate magnetic shield to the parts. During the plating process, the bath solution also would penetrate into the surface of the magnet because of the porous characteristics of NdFeB and the magnetism would be reduced irreversibly. Except the effect of ion, heat can also produce non-ignorable effect, improper temperature would age magnet and reduce coercivity. In addition, during magnetizing process, magnetostrictive effect can cause volume change of the magnet, lead to the inner stress of the layer change, and affect the adhesion between layer and basal material, and finally the layer would lose efficacy. Through different research and test, we have excogitated HN-NdFeB bright barrel nickel plating which has superior performance. Its process characteristic and bath solution composition are described as below.

1.Process characteristic

(1). There has high-speed brightening and excellent leveling.

(2). Bright white and esthetic deposit with good flexibility.

(3). The covering ability is excellent, it can be brightened even in LCD area.

(4). High concentration and low consumption leads lower production cost.

2. Bath solution composition and operating conditions

Nickel Sulfate 220-280 g/L

Nickel Chloride 40-60 g/L

Boric Acid 35-50 g/L

Brightener HN-NFB 1 0.1-0.2 ml/L

Softener HN-NFB 2 6-10ml/L

Wetting Agent HN-19 1-1.5 ml/L

Temperature 50-60℃

pH Value 4.0-4.8

Voltage 12-16V

HN-NdFeB bright barrel nickel plating